Marine Cooling Systems Technical Tips Newsletter

|

Welcome to the Monthly Technical Tips Newsletter. In conjunction with our goal aimed at serving the retail customer, the purpose of this newsletter is to further assist customers in understanding the basics of the marine products they purchase and own. Your feedback is greatly appreciated and helps us to continue providing you with helpful information. Please feel free to respond back to us and let us know if this type of information is valuable to you, as well as suggesting future topics you would like to see included [email protected].

“MARINE COOLING SYSTEMS”

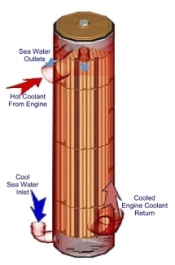

Fresh Water Cooling Fresh Water Cooling vs. Raw Water Cooling, Open Cooling vs. Closed Cooling, 1/2 vs. Full Systems . This months technical tips letter is aimed at addressing many of the common questions and misunderstandings relating to the different types of Marine Cooling Systems. This time of year after going through the pains of draining the engine in preparation for cold weather , many are ready to investigate the various benefits of the closed type of cooling system. Relating to the Marine industry Closed Cooling refers to a cooling system that utilizes a closed/pressurized system containing a standard antifreeze type mixture within the engine block and/or exhaust manifolds. These types of systems utilize some type of a a heat exchanger to remove the heat from the antifreeze. Most common are the standard tube in shell type heat exchanger….. Read More About Fresh Water Cooling Heat Exchangers

Engine cooler units are very similar to oil & power steering coolers and vary in size most commonly between 4″ & 5″. The terminology “# of passes” refers to the dividers in the raw water portion of the cooler and usually range between 3 & 6 in number. When looking at these “passes” when removing the end cap of the cooler and looking into the end they will appear as dividers similar to a pie being cut into pieces. This effect of this is that the water flow velocity is increased and therefore coolant efficiency is benefited. One common misconception is that increasing the coolant flow rate and velocity therefore does not allow the coolant time to properly remove the heat from the system. Marine Water Pumps

Regarding marine water pumps there are two different pumps of most concern; circulating pumps & raw water pumps . The circulating pump is very much like the pump on an automotive engine except with a bronze impeller, ceramic face seals and stainless steel backing plate. These pumps are typically bi-directional and fall into the category of “centrifugal pumps”.

The other pump family is a positive displacement pump meaning it actually produces lift capacity and can be thought of as the pump that supplies the raw water to the circulating pump in an open cooling system. In a closed cooling system this actually pumps the raw water through the raw water (tube) side of the heat exchanger. This raw water is then removing the heat from the anti freeze that the circulating pump is circulating through the engines and/or manifolds. Raw water pumps are typically belt driven, crankshaft driven, or in Mercruiser case with the Alpha sterndrive mounted inside the lower unit of the outdrive. One of the most common misunderstandings regarding pumps and heat exchangers is the thought that simply increasing the size of the heat exchanger will always increase the overall capacity of the system. The amount of raw water flow ultimately limits the efficiency of the system and therefore it is important to size the heat exchanger in conjunction with a pump that will provide an adequate flow rate to yield the proper operating temperature. Technical Information Library

Fresh Water Cooling vs. Raw Water Cooling, Open Cooling vs. Closed Cooling, . This months technical tips letter is aimed at addressing many of the common questions and misunderstandings relating to the different types of Marine Cooling Systems. This time of year after going through the pains of draining the engine in , many are ready to investigate the various benefits of the closed type of cooling system. Relating to the Marine industry Closed Cooling refers to a cooling system that utilizes a closed/pressurized system containing a standard within the engine block and/or exhaust manifolds. These types of systems utilize some type of a a heat exchanger to remove the heat from the antifreeze. Most common are the standard tube in shell type heat exchanger….. Although the more common version of is the tube and shell cooler. There is another system which is called a Keel Cooler, however this type of system will not be addressed in this letter. The typical Marine heat exchanger utilizes a bundle of copper tubes surrounded by a copper shell.Engine cooler units are very similar to and vary in size most commonly between 4″ & 5″. The terminology “# of passes” refers to the dividers in the raw water portion of the cooler and usually range between 3 & 6 in number. When looking at these “passes” when removing the end cap of the cooler and looking into the end they will appear as dividers similar to a pie being cut into pieces. This effect of this is that the water flow velocity is increased and therefore coolant efficiency is benefited. One common misconception is that increasing the coolant flow rate and velocity therefore does not allow the coolant time to properly remove the heat from the system. Regarding marine water pumps there are two different pumps of most concern; & . The circulating pump is very much like the pump on an automotive engine except with a bronze impeller, ceramic face seals and stainless steel backing plate. These pumps are typically bi-directional and fall into the category of “centrifugal pumps”. The other pump family is a positive displacement pump meaning it actually produces lift capacity and can be thought of as the pump that supplies the raw water to the circulating pump in an open cooling system. In a closed cooling system this actually pumps the raw water through the raw water (tube) side of the heat exchanger. This raw water is then removing the heat from the anti freeze that the circulating pump is circulating through the engines and/or manifolds. Raw water pumps are typically belt driven, crankshaft driven, or in Mercruiser case with the Alpha sterndrive mounted inside the lower unit of the outdrive. One of the most common misunderstandings regarding pumps and heat exchangers is the thought that simply increasing the size of the heat exchanger will always increase the overall capacity of the system. The amount of raw water flow ultimately limits the efficiency of the system and therefore it is important to size the heat exchanger in conjunction with a pump that will provide an adequate flow rate to yield the proper operating temperature. |