Marine Fresh Water Cooling System Maintenance Tips

| Location & Service | When Starting Engine Each Day | After Use Each Day | Every 30 Days | After 1st 20 hours | Every 50 Hours | Every 100 Hours | Once/Year | Once/2 Years | Storage |

| Check for Leaks | X | ||||||||

| Maintain Coolant Level | X | ||||||||

| Flush Seawater Section of Cooler | X | ||||||||

| Check for Marine Growth or Debris at Water Pickup | X | ||||||||

| Fasteners – Check for Tightness | X | X | X | ||||||

| Hose Clamps – Check for Tightness | X | X | X | ||||||

| Drive Belts – Inspect | X | X | X | ||||||

| Check and/or Replace Anodes | X | X | |||||||

| Hoses – Check for Cracks and Wear | X | X | |||||||

| Pressure Cap – Clean, Inspect & Test | X | X | |||||||

| Seawater Pickup | X | ||||||||

| Remove Debris on Raw Water Side | X | ||||||||

| Check Corrosion Inhibitor Status of Coolant | X | ||||||||

| Replace Raw Water Pump Impeller | X | ||||||||

| Change Coolant | X | ||||||||

| Clean Closed Coolant Section | X | ||||||||

| Drain and Clean Raw Water Section | X |

WARNING : Never remove pressure cap from a hot system. Allow system to cool down. Turn pressure cap 1/4 turn to allow pressure to escape slowly. Then push down & turn pressure cap off completely.

Maintain coolant level

Before starting engine always, check coolant level in expansion tank. See fill & start up instructions. If coolant level is down, check for leaks in the system and repair. See trouble shooting instructions.

Check for marine growth

Check for marine growth or debris at water pickup. Clean, if necessary.

Make sure drive belts on the engine are tight so that the system pumps will function properly. Check their condition, and replace as required.

Check zinc anode (If Present)

Zinc anode should be checked every 50 hours of operation or at least annually. If zinc part of plug is corroded to a point or less than half its original size, replace it.

Clean and inspect pressure cap

The pressure cap is designed to hold a pressure of 16psi (110kPa) in the closed coolant system. This raises the boiling point of the coolant, raising its efficiency. Carefully remove the cap from the system. Wash the cap and the filler neck with clean water to remove any deposits or debris. Inspect the cap seals for cuts, cracks, or other signs of deterioration. Replace the cap if it is bad.

Remove debris on raw-water side

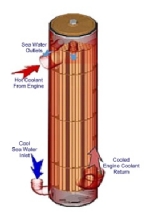

Raw-water sediment and debris may accumulate inside the heat exchanger. This debris may interfere with proper flow, causing overheating and increased wear of heat exchanger. The extent to which debris will build up depends on local water conditions and whether or not strainers or other devices are installed on the raw water inlet.

To clear debris from the heat exchanger, remove the end covers. Clear any accumulated debris. If a more thorough cleaning appears to be warranted, see “Debris blockage” and “Dirt buildup” in the troubleshooting guide. Upon reinstalling end covers, it may be necessary to use new gaskets. If frequent clean outs are necessary install strainers.

Corrosion inhibitor check

To obtain maximum benefits from FWC, the coolant should contain sufficient concentration of corrosion inhibitors. This inhibitor concentration should be checked every year by testing the solution for proper alkalinity level. Do this by using litmus paper. Paper will turn blue if coolant is alkaline and safe. If paper remains pink, coolant is acidic and should be replaced. Coolant in freshwater cooling system should be changed every 2 years.

General MARINE ENGINE winterizing

A freshwater cooling system is much easier to winterize than a raw-water cooling system since antifreeze solution already should be present on the freshwater side of the system. However, the raw-water part of the system must be properly winterized in order to prevent damage.

Before winterizing the cooling system, make sure that the rest of the engine has been properly winterized. Carefully study the engine manufacturer’s instructions and make sure that all the procedures that require running the engine have been performed. We assume that the engine, as part of the general winterizing, has been operated with a garden hose as raw-water supply.

Make sure that the raw-water side of the cooling system has received a thorough flushing before starting to winterize cooling system.

Freshwater sideCheck freshwater part of system to make sure that it contains antifreeze solution of sufficient concentration to handle the lowest temperatures expected in your area. Use a standard automotive type antifreeze tester. As to necessary strength, check information printed on antifreeze container or the chart in the flush and fill directions.

In addition, check the corrosion inhibitor concentration as outlined in general maintenance. For best protection, change antifreeze at least every other year or whenever the test indicates insufficient corrosion inhibitor concentration.

Raw-water side

Drain and clean raw-water side

Remove drain plug and zinc anodes from heat exchanger to drain raw-water. Remove demountable end covers and thoroughly remove any debris including zinc anode particles (if system has anode) that may have accumulated. Unless this debris is removed, it may not be possible to fully drain all the small internal tubes. It only takes trapped water in one tube to crack the tube and create a leaking heat exchanger.

Freeze damage is not covered under warranty, so make sure that a thorough job is done.

Be especially careful with horizontally mounted heat exchangers since capillary action tends to hold water in tubes. If compressed air is available, blow out any water trapped this way.

Reinstall drain plug, zinc anodes, and end covers. Upon reinstalling end covers, it may be necessary to use new gaskets.

Drain raw-water pump

Remove end cover from pump to let it drain. For best results, remove rubber impeller from pump. Spray it with silicone oil and store it separately to be used as a spare next season. Install fresh impeller every new season in order to make sure that raw-water pump functions properly. If convenient remove the entire pump from the engine and store it in a non-freezing area. For stern drive engine(s) with pump in stern drive, follow manufacturers instructions.

Drain engine on raw-water side

Following engine manufacturers instructions, drain all additional parts on raw-water system such as strainers, hoses, oil coolers, and exhaust system components.

Fill raw-water system with antifreeze

Draining all the raw-water from the system will protect the raw-water side from freeze damage. However, in order to protect the system from corrosion during storage fill the entire raw-water side with antifreeze that contains corrosion inhibitors. It also adds additional freeze protection in case the draining of the raw-water side was less than perfect.

Without running the engine, fill the raw-water side through a hose attached to the lowest part of the system. Leave drain plugs out but have them ready. Reinstall the plugs as the antifreeze reaches the different components and levels. By letting the antifreeze spill out before you reinstall the plug, you know the antifreeze reached everything without creating air pockets.

Check for leaks

Check to make sure there are no leaks on freshwater or raw-water side.

Remove end cover from pump to let it drain. For best results, remove rubber impeller from pump. Spray it with silicone oil and store it separately to be used as a spare next season. Install fresh impeller every new season in order to make sure that raw-water pump functions properly. If convenient remove the entire pump from the engine and store it in a non-freezing area. For stern drive engine(s) with pump in stern drive, follow manufacturers instructions.Drain engine on raw-water side Following engine manufacturers instructions, drain all additional parts on raw-water system such as strainers, hoses, oil coolers, and exhaust system components.

Remove end cover from pump to let it drain. For best results, remove rubber impeller from pump. Spray it with silicone oil and store it separately to be used as a spare next season. Install fresh impeller every new season in order to make sure that raw-water pump functions properly. If convenient remove the entire pump from the engine and store it in a non-freezing area. For stern drive engine(s) with pump in stern drive, follow manufacturers instructions.Following engine manufacturers instructions, drain all additional parts on raw-water system such as strainers, hoses, oil coolers, and exhaust system components. Fill raw-water system with antifreeze Draining all the raw-water from the system will protect the raw-water side from freeze damage. However, in order to protect the system from corrosion during storage fill the entire raw-water side with antifreeze that contains corrosion inhibitors. It also adds additional freeze protection in case the draining of the raw-water side was less than perfect. Check to make sure there are no leaks on freshwater or raw-water side.

Remove end cover from pump to let it drain. For best results, remove rubber impeller from pump. Spray it with silicone oil and store it separately to be used as a spare next season. Install fresh impeller every new season in order to make sure that raw-water pump functions properly. If convenient remove the entire pump from the engine and store it in a non-freezing area. For stern drive engine(s) with pump in stern drive, follow manufacturers instructions.Following engine manufacturers instructions, drain all additional parts on raw-water system such as strainers, hoses, oil coolers, and exhaust system components. Fill raw-water system with antifreeze Draining all the raw-water from the system will protect the raw-water side from freeze damage. However, in order to protect the system from corrosion during storage fill the entire raw-water side with antifreeze that contains corrosion inhibitors. It also adds additional freeze protection in case the draining of the raw-water side was less than perfect. Check to make sure there are no leaks on freshwater or raw-water side.