High Capacity versus Standard Capacity Marine Fresh Water Cooling Systems

The main area of difference with a Premium System is that coolant is forced thru the exhaust manifolds before it passes through the heat exchanger thus it is referred to as a full flow system. With these type systems flow is maintained throughout the exhaust manifolds and engine block at all times and therefore potential “Hot Spots” are minimized. These systems utilize a dual acting type thermostat which regulates an internal bypass system such that even when the thermostat is in the closed position full flow is maintained through the engine.

Standard Systems

These system have bypass functionality integrated into the thermostat to allow a small amount of flow thru the thermostat in the closed position. Thus when the engine is cold the only flow thru the engine is what bypasses thru the thermostat bypass. This also prevents the exhaust manifolds from over-heating during engine warm up.

High Capacity

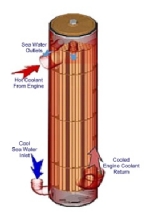

This term is used to describe particular design features such as 6 raw water passes, a tighter tube pitch meaning a higher number of cooling tubes, sealed dividers which means leakage between the passages is minimized. All of these features require a higher level of material and labor and therefore typically indicate a higher cost. This also typically indicates a heavier unit due to having more internal cooling material. Although overall system capacity is ultimately determined by the capacity of the raw water pump supply the efficiency of the heat exchanger allows the high capacity systems to compensate for the lower flowing pumps and therefore provide a higher overall system margin.