Spark Plugs for Inboard Engines

Examples of Spark Plug Conditions

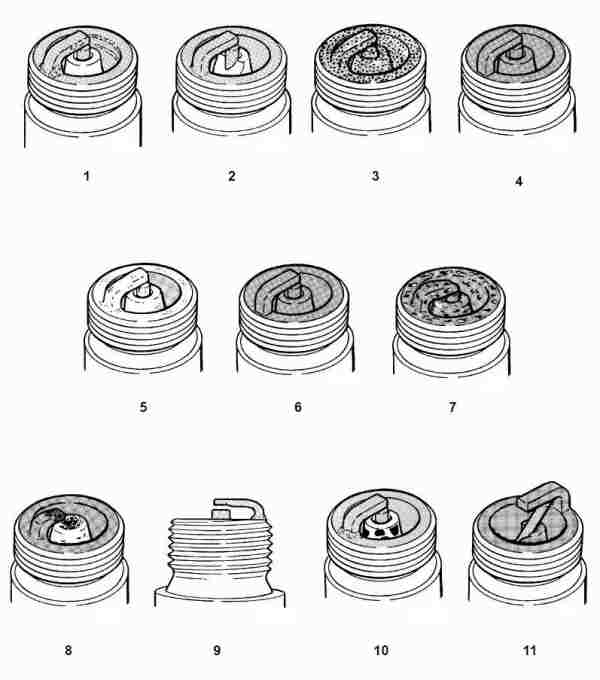

Visually examine the spark plugs as previously outlined, and compare your spark plug to the following information:

1 Normal Condition – Few deposits are present and probably will be light tan or gray in color. This plug shows that plug heat range is compatible with engine, and engine is electrically and mechanically in good running condition. With proper plug servicing (clean and re-gap), this plug can be reinstalled with good results.

2 Chipped Insulator – Chipped insulator usually results from careless plug re-gapping. Under certain conditions, severe detonation also can split insulator firing ends. Plug must be replaced.

3 Wet Fouling (Oil Deposits) – Plug becomes shorted by excessive oil entering combustion chamber, usually in engine with many hours of operation. Worn piston rings, cylinder walls, valve guides or valve stem seals are causes of oil entering combustion chamber. Only engine repairs will permanently relieve oil wet fouling.

IMPORTANT: New engines or recently overhauled engines may wet foul plugs before normal oil control is achieved with proper break-in procedures. Such fouled plugs may be serviced (clean and re-gap) and reinstalled.

4 Cold Fouling – Dry, black deposits indicate rich fuel mixture or weak ignition. Clogged flame arrestor, flooding carburetor, sticky choke or weak ignition components all are probably causes. If, however, only one or two plugs in set are fouled, check for sticking valves or bad ignition leads. After correcting cause, service (clean and re-gap) plugs and reinstall.

5 Overheating – Insulator is dull white or gray and appears blistered. Electrodes are eroded and there is an absence of deposits. Check that correct plug heat range is being used. Also check for over-advanced ignition timing, cooling system malfunction, lean fuel/air mixtures, leaking intake manifold or sticking valves. Replace spark plugs.

6 High Speed Glazing – Insulator has yellowish, varnish-like color, indicating that temperatures suddenly have risen, usually during hard, fast acceleration under heavy load. Normal deposits do not get a chance to blow off. Instead, they melt and form a conductive coating. Replace plugs. If condition recurs, use colder heat range plug and service plugs more frequently.

7 Scavenger Deposits – Powdery white or yellow deposits are built up on shell, insulator and electrodes. This is normal appearance with certain branded fuels. Accumulation on ground electrodes and shell areas may be unusually heavy, but may be easily chipped off. Plugs can be serviced (clean and re-gap) and reinstalled.

8 Pre-Ignition Damage – Pre-ignition damage is caused by excessive high temperatures. Center electrode melts first, followed by ground electrode. Normally, insulators are white but may be dirty if plug has been misfiring. Check for correct plug heat range, advance ignition timing, lean fuel mixture, incorrect fuel used, malfunctioning cooling system, leaking intake manifold or lack of lubrication.

9 Reversed Coil Polarity – Concave erosion of ground electrode is an indication of reversed polarity. Center electrode will show only normal wear. Engine will misfire and idle rough. To correct, reverse primary coil leads. Replace spark plugs.

10 Splashed Deposits – Spotted deposits, which sometimes occur after long delayed tune-up, accumulate after a long period of misfiring. When normal combustion temperatures are restored, upon installation of new plugs, deposits loosen from top of piston and head and are thrown against hot insulator. Clean and re-gap plugs and reinstall.

11 Mechanical Damage – Mechanical damage to spark plug firing end is caused by foreign object in combustion chamber. Because of valve overlap, small objects can travel from one cylinder to another. Check all cylinders, intake manifold and exhaust material to prevent further damage.